Features:

1. One piece cast iron frame, providing sufficient stability and strength.

2. Complete safety hood against noise and dust, with automatic power OFF protection for opening.

3. The main spindles are processed, assembled and dynamically balanced, guaranteeing superior stability and accuracy.

4. The work table surface adopts special material and is hard chromed, providing sufficient wear-resistance.

5. Feeding system adopts front, middle and rear three section pneumatic hold-down mechanisms, providing stable pressure and easy adjustments.

6. More motorized bottom feeding rollers are applied to the work table, from the front to the rear end, guaranteeing perfect feeding performance.

7. Manual pump for centralized lubrication of the work table surface and dovetail plates. No more overlooked lubrication points maintenance.

8. The first bottom spindle is equipped with straightening cutter groove and the front and rear table plate is inlayed with alloy steel plates, guaranteeing precise processing quality and wear-resistance.

9. Pneumatic switch on the operation panel controls the first two groups of wheels for quick engagement and disengagement, for planing or straightening.

10. The second bottom spindle is able to do works of multiple rip saw.

11. All the electric components and transmission units are purchased form quality international brands, guaranteeing reliability.

12. Variable feeding speed controlled by the frequency converter with digital display, feeding speed from 5-26 m/min.

13. Easy- to -understand operation panel. Everything at a glance and under control.

Optional:

1.CE configuration.

2. Enhance capacitance of the power of electrical power shaft.

3. The feeding table is increased by 2500-3000.

4. The surface of the electrical pump lubricating table.

5. Every main axis adopts brake system.

6. Every shaft is activated by Y-△。

7. QMB623A-K is installed with a computer touch screen.

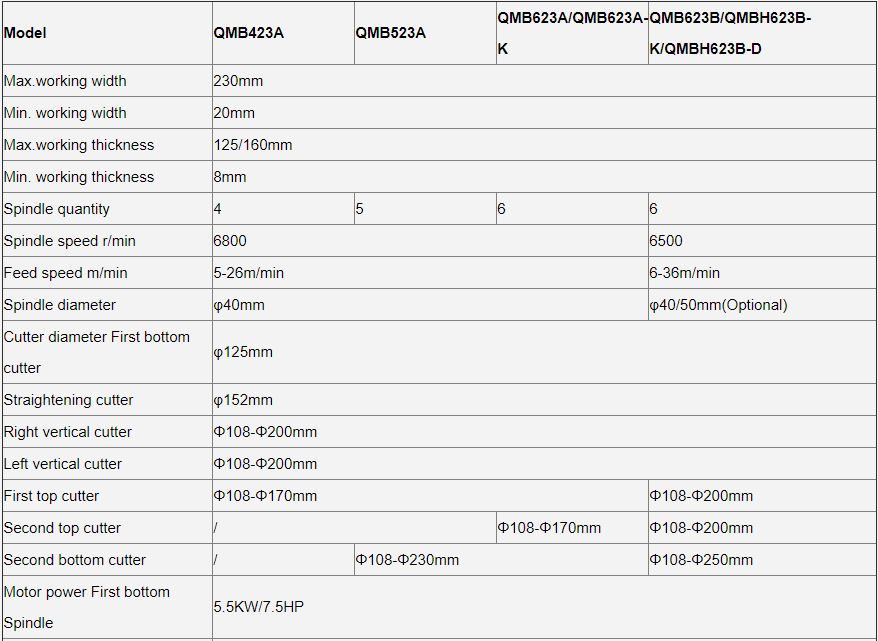

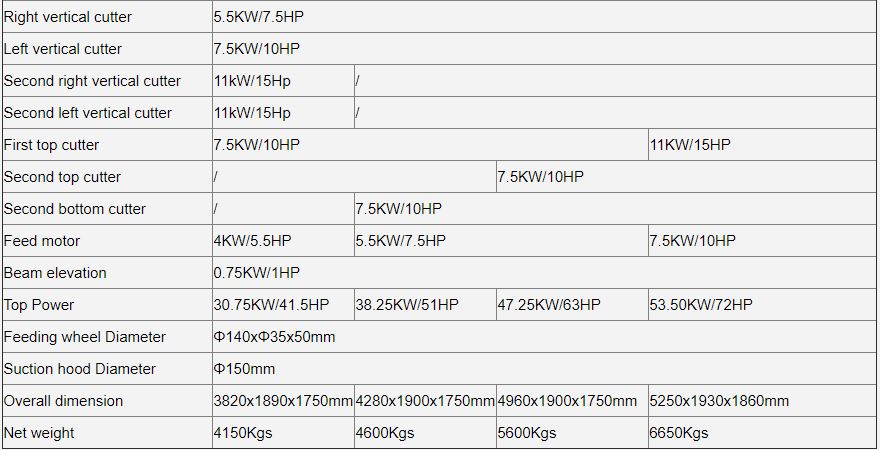

Specifications: